A resistor is one of the most fundamental components in electronics. Its purpose is to impede a flow of current and impose a voltage reduction. It consists of two wires or conductors attached at opposite ends or sides of a relatively poor electrical conductor, the resistance of which is measured in ohms, universally represented by the Greek omega symbol, Ω.

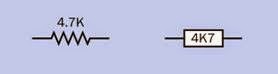

Schematic symbols that represent a resistor are shown in Figure 10-1 (Left: The traditional schematic symbol. Right: The more recent European equivalent). The US symbol is still sometimes used in European schematics, and the European symbol is sometimes used in US schematics. Letters K or M indicate that the value shown for the resistor is in thousands of ohms or millions of ohms, respectively. Where these letters are used in Europe, and sometimes in the US, they are substituted for a decimal point. Thus, a 4.7K resistor may be identified as 4K7, a 3.3M resistor may be identified as 3M3, and so on. (The numeric value in Figure 10-1 was chosen arbitrarily.)

Figure 10-1. Resistor symbols. The left one is more common in the United States, while the right one is widely used in Europe. The 4.7K value was chosen arbitrarily.

A resistor is commonly used for purposes such as limiting the charging rate of a capacitor; pro viding appropriate control voltage to semiconductors such as bipolar transistors; protecting LEDs or other semiconductors from excessive current; adjusting or limiting the frequency response in an audio circuit (in conjunction with other components); pulling up or pulling down the voltage at the input pin of a digital logic chip; or controlling a voltage at a point in a circuit. In this last application, two resistors may be placed in series to create a voltage divider.

A potentiometer may be used instead of a resistor where variable resistance is required.

Sample resistors of various values are shown in Figure 10-2. From top to bottom, their power dissipation ratings are 3W, 1W, 1/2W, 1/4W, 1/4W, 1/4W, and 1/8W. The accuracy (tolerance) of each resistor, from top to bottom, is plus-or-minus 5%, 5%, 5%, 1%, 1%, 5%, and 1%. The beige-colored body of a resistor is often an indication that its tolerance is 5%, while a blue-colored body often indicates a tolerance of 1% or 2%. The blue- bodied resistors and the dark brown resistor contain metal-oxide film elements, while the beige- bodied resistors and the green resistor contain carbon film. For more information on resistor values, see the upcoming Values section.

Figure 10-2. A range of typical resistors. See text for de- tails.

In the process of impeding the flow of current and reducing voltage, a resistor absorbs electrical energy, which it must dissipate as heat. In most modern electronic circuits, the heat dissi pation is typically a fraction of a watt.

If R is the resistance in ohms, I is the current flowing through the resistor in amperes, and V is the voltage drop imposed by the resistor (the difference in electrical potential between the two con tacts that are attached to it), Ohm’s law states:

V = I / R

This is another way of saying that a resistor of 1Ω will allow a current of 1 amp when the potential difference between the ends of the resistor is 1 volt.

If W is the power in watts dissipated by the resistor, in a DC circuit:

W = V * I

By substitution in Ohm’s law, we can express watts in terms of current and resistance:

W = I2 / R

We can also express watts in terms of voltage and resistance:

W = V2 * R

These alternates may be useful in situations where you do not know the voltage drop or the current, respectively.

Approximately similar relationships exist when using alternating current, although the power will be a more complex function.

Axial resistors have two leads that emerge from opposite ends of a usually cylindrical body. Ra dial resistors have parallel leads emerging from one side of the body and are unusual.

Precision resistors are generally defined as having a tolerance of no more than plus-or-minus 1%.

General-purpose resistors are less stable, and their value is less precise.

Power resistors are generally defined as dissipating 1 or 2 watts or more, particularly in power supplies or power amplifiers. They are physically larger and may require heat sinks or fan cooling.

Wire-wound resistors are used where the component must withstand substantial heat. A wire- wound resistor often consists of an insulating tube or core that is flat or cylindrical, with multiple turns of resistive wire wrapped around it. The wire is usually a nickel-chromium alloy known as nichrome (sometimes written as Ni-chrome) and is dipped in a protecting coating.

The heat created by current passing through resistive wire is a potential problem in electronic circuits where temperature must be limited. However, in household appliances such as hair dryers, toaster ovens, and fan heaters, a nichrome element is used specifically to generate heat. Wire-wound resistors are also used in 3D printers to melt plastic (or some other com pound) that forms the solid output of the device.

Thick film resistors are sometimes manufactured in a flat, square format. A sample is shown in Figure 10-3, rated to dissipate 10W from its flat surface. The resistance of this component is 1K.

Figure 10-3. A thick-film resistor measuring about 1” square and 0.03” thick.

Surface-mount resistors generally consist of a resistive ink film printed on top of a tablet of aluminum oxide ceramic compound, often approximately 6mm long, known as a 2512 form factor. Each surface-mount resistor has two nickel-

plated terminations coated in solder, which melts when the resistor is attached to the circuit board. The upper surface is coated, usually with black epoxy, to protect the resistive element.

This is also known as a resistor network or resistor ladder, and consists of a chip containing multiple equal-valued resistors.

A resistor array in a single-inline package (or SIP) may have three possible internal configurations: isolated, common bus, and dual terminator. These options are shown at top, center, and bot tom, respectively, in Figure 10-4. The isolated variant is commonly available in SIPs with 6, 8, or 10 pins. The common-bus and dual-terminator configurations generally have 8, 9, 10, or 11 pins.

In the isolated configuration, each resistor is electrically independent of the others and is accessed via its own pair of pins. On a common bus, one end of each resistor shares a bus accessed by a single pin, while the other ends of the resistors are accessed by their own separate pins. A dual- terminator configuration is more complex, consisting of pairs of resistors connected between ground and an internal bus, with the midpoint of each resistor pair accessible via a separate pin. The resistor pairs this function as voltage dividers and are commonly used in emitter-coupled logic circuits that require termination with -2 volts.

A dual-inline package (DIP) allows a similar range of internal configurations, as shown in Figure 10-5. At top, isolated resistors are commonly available in DIPs with 4, 7, 8, 9, or 10 pins. At center, the common bus configuration is avail able in DIPs with 8, 14, 16, 18, or 20 pins. At bot tom, the dual-terminator configuration usually has 8, 14, 16, 18, or 20 pins.

The external appearance of SIP and DIP resistor arrays is shown in Figure 10-6. From left to right, the packages contain seven 120Ω resistors in

Figure 10-4. Multiple resistors can be embedded in a single-inline package (SIP) in a variety of formats. See text for additional details.

isolated configuration; thirteen 120Ω resistors in bussed configuration; seven 5.6K resistors in bussed configuration; and six 1K resistors in bussed configuration.

Resistor arrays with isolated or common-bus configurations are a convenient way to reduce the component count in circuits where pullup, pulldown, or terminating resistors are required for multiple chips. The common-bus configuration is also useful in conjunction with a 7-

Figure 10-5. Multiple resistors can be obtained embedded in a dual-inline package (DIP). See text for additional details.

segment LED display, where each segment must be terminated by a series resistor and all the resistors share a common ground or common voltage source.

Surface-mount chips are available containing a pair of resistors configured as a single voltage divider.

Chips containing multiple RC circuits (each consisting of a capacitor and a resistor in series) are available, although uncommon. A package containing a single RC circuit may be sold as a

snubber to protect contacts in a switch or re lay that switches a large inductive load. More in formation on snubber circuits is in the capaci tor entry of this encyclopedia; see “Snubber” (page 108).

1 kilohm, usually written as 1K, is 1,000Ω. 1 meg ohm, usually written as 1M or 1 meg, is 1,000K. 1 gig Naohm is 1,000 megs, although the unit is rarely used. Resistances of less than 1Ω are uncommon and are usually expressed as a decimal number followed by the Ω symbol. The term milliohms (thousandths of an ohm) is used in special appli cations. Equivalent resistor values are shown in Figure 10-7.

A resistance value remains unchanged in DC and AC circuits, except where the AC reaches an extremely high frequency.

In common electronics applications, resistances usually range from 100Ω to 10M. Power ratings may vary from 1/16 watt to 1000 watts, but usu ally range from 1/8 watt to 1/2 watt in most electronic circuits (less in surface-mount applications).

Figure 10-7. Equivalent values in ohms, kilohms, and megohms.

The tolerance, or precision, of a resistor may range from plus-or-minus 0.001% up to plus-or- minus 20%, but is most commonly plus-or-minus 1%, 2%, 5%, or 10%.

The traditional range of resistor values was es tablished when a tolerance of 20% was the norm. The values were spaced to allow minimum risk of a resistor at one end of its tolerance range having the same value as another resistor at the oppo site end of its tolerance range. The values were rounded to 10, 15, 22, 33, 47, 68, and 100, as illustrated in Figure 10-8 where each blue dia mond represents the possible range of actual values of a 20% resistor with a theoretical value shown by the white horizontal line at the center of the diamond.

Resistor factors repeat themselves in multiples of

10. Thus, for example, beginning with a resistor of 100Ω, subsequent increasing values will be 150, 220, 330, 470, 680, and 1K, whereas the range of resistors beginning with 1Ω will be 1.5, 2.2, 3.3, 4.7, 6.8, and 10Ω.

Resistance multiplication factors are now ex pressed as a list of preferred values by the Inter national Electrotechnical Commission (IEC) in their 60063 standard. Intermediate factors have been added to the basic sequence to

Figure 10-8. Graphical representation of standard resistor values (white lines) established by the International Electrotechnical Commission, showing the acceptable range of actual values (dark blue areas) assuming precision of plus-or-minus 20%. The overlap, if any, between each range and the next is shown in black.

accommodate better tolerances. A table showing resistor values for tolerances of plus-or- minus 20%, 10%, and 5% appears in Figure 10-9. Resistors with a tolerance of 5% have become increasingly common.

Figure 10-9. Standard values for resistors of different precisions. For resistors outside the range shown, values can be found by multiplying or dividing (repeatedly, if necessary) by a factor of 10.

The IEC has established 3-digit preferred values for resistors with values accurate to plus-or- minus 0.5%.

Because many capacitors still have a tolerance no better than 20%, their values also conform with

the old original set of resistance values, although the units are expressed in farads or fractions of a farad. See the capacitors entry in this encyclopedia for additional information.

Through-hole axial resistors are traditionally printed with a sequence of three colored bands to express the value of the component, each of the first two bands representing a digit from 0 through 9, while the third band indicates the decimal multiplier (the number of zeroes, from 0 to 9, which should be appended to the digits). A fourth band of silver or gold indicates 10% or 5% tolerance respectively. No fourth band would indicate 20% tolerance, although this has become very rare.

Many resistors now have five color bands, to en able the representation of intermediate or fractional values. In this scheme, the first three bands have numeric values (using the same color sys tem as before) while the fourth band is the multiplier. A fifth band, at the opposite end of the resistor, indicates its tolerance.

In Figure 10-10 the numeric or multiplier value of each color is shown as a “spectrum” at the top of the figure. The tolerance, or precision of a resistor, expressed as a plus-or-minus percentage, is shown using silver, gold, and various colors, at the bottom of the figure.

Two sample resistors are shown. The upper one has a value of 1K, indicated by the brown and black bands on the left (representing numeral 1 followed by a numeral 0) and the third red band (indicating two additional zeroes). The gold band at right indicates a precision of 5%. The lower one has a value of 1.05K, indicated by the brown, black, and green bands on the left (representing numeral 1 followed by numeral 0 followed by a numeral 5) and the fourth band brown (indicating one additional zero). The brown band at right indicates a precision of 1%.

Figure 10-10. Color coding of through-hole resistors. See text for details.

In extremely old equipment, resistors may be co ded with the body-tip-dot scheme, in which the body color represents the initial digit, the end color represents the second digit, and a dot rep resents the multiplier. The numeric identities of the colors is the same as in the current color scheme.

In all modern schemes, the three or four bands that show the resistance value are spaced close together, while a larger gap separates them from the band that shows the tolerance. The resistor value should be read while holding the resistor so that the group of closely-spaced numeric bands is on the left.

Confusingly, some resistors may be found where the first three bands define the value, using the old three-band convention; the fourth band in dicates tolerance; and a fifth band at the oppo site end of the component indicates reliability. However, this color scheme is uncommon.

Other color-coding conventions may be found in special applications, such as military equipment.

It is common for through-hole carbon-film resistors to have a beige body color, while through- hole metal-film resistors often have a blue body color. However, in relatively rare instances, a blue body color may also indicate a fusible resistor (designed to burn out harmlessly like a fuse, if it is overloaded) while a white body may indicate a non-flammable resistor. Use caution when re placing these special types.

Some modern resistors may have their values printed on them numerically. Surface-mount resistors also have digits printed on them, but they are a code, not a direct representation of resist ance. The last digit indicates the number of zeroes in the resistor value, while the preceding two or three numbers define the value itself. Letter R is used to indicate a decimal point. Thus a 3R3 surface-mount resistor has a value of 3.3Ω, while 330 would indicate 33Ω, and 332 indicates 3,300Ω. A 2152 surface-mount resistor would have a value of 21,500Ω.

A surface-mount resistor with a single zero printed on it is a zero ohm component that has the same function as a jumper wire. It is used for convenience, as it is easily inserted by automated production-line equipment. It functions merely as a bridge between traces on the circuit board.

When resistor values are printed on paper in schematics, poor reproduction may result in omission of decimal points or introduction of specks that look like decimal points. Europeans have addressed this issue by using the letter as a substitute for a decimal point so that a 5.6K resistor will be shown as 5K6, or a 3.3M resistor will be shown as 3M3. This practice is followed infre quently in the United States.

This term describes the ability of a resistor to maintain an accurate value despite factors such as temperature, humidity, vibration, load cycling, current, and voltage. The temperature coeffi cient of a resistor (often referred to as Tcr or Tc, not to be confused with the time constant of a charging capacitor) is expressed in parts per million

change in resistance for each degree centigrade deviation from room temperature (usually assumed to be 25 degrees Centigrade). Tcmay be a positive or a negative value.

The voltage coefficient of resistance—often ex pressed as Vc—describes the change of a resistor’s value that may occur as a function of changes in voltage. This is usually significant only where the resistive element is carbon-based. If V1 is the rated voltage of the resistor, R1 is its rated resistance at that voltage, V2 is 10% of the rated voltage, and R2 is the actual resistance at that voltage, the voltage coefficient, Vc, is given by this formula:

Vc = (100 * (R1 - R2)) / (R2 * (V1 - V2))

Resistors are formed from a variety of materials.

Carbon composite. Particles of carbon are mixed with a binder. The density of the carbon deter mines the end-to-end resistance, which typically ranges from 5Ω to 10M. The disadvantages of this system are low precision (a 10% tolerance is common), relatively high voltage coefficient of re sistance, and introduction of noise in sensitive circuits. However, carbon-composite resistors have low inductance and are relatively tolerant of overload conditions.

Carbon film. A cheap and popular type, made by coating a ceramic substrate with a film of carbon compound. They are available in both through- hole and surface-mount formats. The range of resistor values is comparable with carbon- composite types, but the precision is increased, typically to 5%, by cutting a spiral groove in the carbon-compound coating during the manufac turing process. The carbon film suffers the same disadvantages of carbon composite resistors, but to a lesser extent. Carbon film resistors gen erally should not be substituted for metal film resistors in applications where accuracy is important.

Metal film. A metallic film is deposited on a ce ramic substrate, and has generally superior char

acteristics to carbon-film resistors. During man ufacture, a groove may be cut in the metal film to adjust the end-to-end resistance. This may cause the resistor to have higher inductance than carbon-composite types, though it has lower noise. Tolerances of 5%, 2%, and 1% are available. This type of resistor was originally more expen sive than carbon-film equivalents, but the differ ence is now fractional. They are available in both through-hole and surface-mount formats. They are available in lower-wattage variants (1/8 watt is common).

Thick-film resistors are spray-coated, whereas thin-film resistors are sputtered nichrome. Thin- films enjoy a flatter temperature coefficient and are typically used in environments that have a huge operational temperature range, such as satellites.

Bulk metal foil. The type of foil used in metal film resistors is applied to a ceramic wafer and etched to achieve the desired overall resistance. Typical ly these resistors have axial leads. They can be extremely accurate and stable, but have a limited maximum resistance.

Precision wire-wound. Formerly used in applications requiring great accuracy, but now largely replaced by precision metal foil.

Power wire-wound. Generally used when 1 or 2 watts or more power dissipation is required. Resistive wire is wrapped around a core that is often ceramic. This can cause the resistor to be referred to, inaccurately, as “ceramic.” The core may alter natively be fiberglass or some other electrically insulating compound that actively sinks heat. The component is either dipped (typically in vitreous enamel or cement) or is mounted in an aluminum shell that can be clamped to a heat sink. It almost always has the ohm value printed on it in plain numerals (not codes).

Two typical wire-wound resistors are shown in Figure 10-11. The upper resistor is rated at 12W and 180Ω while the lower resistor is rated at 13W and 15K.

Figure 10-11. Two wire-wound resistors of greatly differ- ing resistance but similar power dissipation capability.

A larger wire-wound resistor is shown in

Figure 10-12, rated for 25W and 10Ω.

Figure 10-12. A large wirewound resistor rated to dissipate 25W.

In Figure 10-13, two resistors encapsulated in cement coatings are shown with the coatings re moved to expose the elements. At left is a 1.5Ω 5W resistor, which uses a wire-wound element. At right is a very low-value 0.03Ω 10W resistor.

Figure 10-13. Two low-value resistors with their cement coatings removed to show the resistive elements.

In Figure 10-14, the resistor at right has an ex posed 30Ω element while the resistor at left is rated 10W and 6.5Ω, enclosed in an anodized aluminum shell to promote heat dissipation.

Figure 10-14. A 30Ω resistor (right) and 6.5Ω resistor (left).

In power resistors, heat dissipation becomes an important consideration. If other factors (such as voltage) remain the same, a lower-value resistor will tend to pass more current than a higher- value resistor, and heat dissipation is proportion al to the square of the current. Therefore power wire-wound resistors are more likely to be needed where low resistance values are required. Their coiled-wire format creates significant inductance, making them unsuitable to pass high frequencies or pulses.

Some of the most common applications for a resistor are listed here.

To protect an LED from damage caused by excessive current, a series resistor is chosen to allow a current that does not exceed the manufacturer’s specification. In the case of a single through- hole LED (often referred to as an indicator), the forward current is often limited to around 20mA, and the value of the resistor will depend on the voltage being used. (See Figure 10-15.)

When using high-output LEDs (which may contain multiple elements in a single 5mm or 10mm package), or LED arrays that are now being used for domestic lighting, the acceptable current may be much greater, and the LED unit may contain its own current-limiting electronics. A data sheet should be consulted for details.

Figure 10-15. A series resistor is necessary to limit the current that passes through an LED.

Current Limiting with a Transistor In Figure 10-16, a transistor is switching or am plifying current flowing from B to C. A resistor is used to protect the base of the transistor fromexcessive current flowing from point A. Resistorsare also commonly used to prevent excessive current from flowing between B and C.

Figure 10-16. A resistor is typically necessary to protect the base of a transistor from excessive current.

When a mechanical switch or pushbutton is at tached to the input of a logic chip or microcon troller, a pullup or pulldown resistor is used, ap plying positive voltage or grounding the pin, re spectively, to prevent it from “floating” in an in determinate state when the switch is open. In Figure 10-17, the upper schematic shows a pull down resistor, whereas the lower schematic shows a pullup resistor. A common value for either of them is 10K. When the pushbutton is pressed, its direct connection to positive voltage or to ground easily overwhelms the effect of the resistor. The choice of pullup or pulldown resistor may depend on the type of chip being used.

A resistor-capacitor combination can limit the high-frequency in a simple audio tone-control circuit, as shown in Figure 10-18. Beneath a signal travelling from A to B, a resistor is placed in series with a capacitor that passes high frequencies to ground. This is known as a low-pass filter.

A resistor will adjust the charge/discharge time when placed in series with a capacitor, as in Figure 10-19. When the switch closes, the resistor limits the rate at which the capacitor will charge itself from the power supply. Because a capacitor has an ideally infinite resistance to DC current, the voltage measured at point A will rise until it

Figure 10-17. A pulldown resistor (top) or pullup resistor (bottom) prevents an input pin on a logic chip or micro- controller from “floating” in an indeterminate state when the button is not being pressed.

Figure 10-18. This configuration may be used to remove high frequencies from an audio signal. It is known as a low-pass filter because low frequencies are passed from A to B.

is close to the supply voltage. This is often referred to as an RC (resistor-capacitor) network and is discussed in greater detail in the capacitor section of this encyclopedia.

Figure 10-19. In an RC (resistor-capacitor) network, a resistor limits the rate of increase in potential of the capaci- tor, measured at A, when the switch is closed.

Two resistors may be used to create a voltage divider (see Figure 10-20). If Vin is the supply volt age, the output voltage, Vout, measured at point A, is found by the formula:

In reality, the actual value of Vout is likely to be affected by how heavily the output is loaded.

If the output node has a high impedance, such as the input to a logic chip or comparator, it will be more susceptible to electrical noise, and lower-value resistors may be needed in the volt age divider to maintain a higher current flow and maintain stability in the attached device.

If resistors in series have values R1, R2, R3 . . . the total resistance, R, is found by summing the in dividual resistances:

Figure 10-20. In a DC circuit, a pair of resistors may be placed in series to function as a voltage divider. The volt- age measured at A will be lower than the supply voltage, but above ground potential.

R = R1 + R2 + R3. . .

The current through each of the resistors will be the same, whereas the voltage across each of them will vary proportionately with its resistance. If the supply voltage across the series of resistors is VS, and the total of all the resistor values is RT, and the resistance of one resistor is R1, the voltage across that resistor, V1, will be given by the formula:

V1 = VS * (R1 / RT)

Where two or more resistors (R1, R2, R3 . . . ) are wired in parallel, their total resistance, R, is found from the formula:

1/R = ( 1/R1 ) + ( 1/R2 ) + ( 1/R3 ). . .

Suppose that R1, R2, R3 . . . all have the same in dividual resistance, represented by RI, and the number of resistors is N. Their total resistance, RT, when wired in parallel, will be:

RT = RI / N

If each resistor has an equal resistance and also has an equal individual rating in watts (represented by WI), the total wattage (WT) that they can handle when wired in parallel to share the power will be:

Therefore, if an application requires high- wattage resistors, multiple lower-wattage, higher-value resistors may be substituted if they are wired in parallel—and may even be cheaper than a single high-wattage wire-wound resistor. For example, if a 5W, 50Ω resistor is specified, 10 resistors can be substituted, each rated at 0.5W and 500Ω. Bear in mind that if they are tightly bundled, this will interfere with heat dissipation.

Resistors are probably the most robust of all electronic components, with high reliability and a long life. It is difficult to damage a resistor by overheating it with a soldering iron.

The wattage rating of a resistor does not necessarily mean that it should be used to dissipate that amount of power on a constant basis. Small resistors (1/4 watt or less) can overheat just as easily as big ones. Generally speaking, it is safe practice not to exceed 75% of a resistor’s power rating on a constant basis.

Overheating is predictably more of a problem for power resistors, where provision must be made for heat dissipation. Issues such as component crowding should be considered when deciding how big a heat sink to use and how much ventilation. Some power resistors may function reliably at temperatures as high as 250 degrees Cen tigrade, but components near them are likely to be less tolerant and plastic enclosures may soft en or melt.

The electrical noise introduced by a resistor in a circuit will vary according to the composition of

the resistor, but for any given component, it will be proportional to voltage and current. Low- noise circuits (such as those at the input stage of a high-gain amplifier) should use low-wattage resistors at a low voltage where possible.

The coiled wire of a wire-wound resistor will be significantly inductive at low frequencies. This is known as parasitic inductance. It will also have a resonant frequency. This type of resistor is un suitable for applications where frequency ex ceeds 50KHz.

When using resistors with 10% tolerance, imprecise values may cause greater problems in some applications than in others. In a voltage divider, for instance, if one resistor happens to be at the high end of its tolerance range while the other happens to be at the low end, the voltage obtained at the intersection of the resistors will vary from its expected value. Using the schematic shown in Figure 10-20, if R1 is rated for 1K and R2 is rated for 5K, and the power supply is rated at 12VDC, the voltage at point A should be:

V = 12 * (( 5 / (5 + 1)) = 10

However, if R1 has an actual value of 1.1K and R2 has an actual value of 4.5K, the actual voltage obtained at point A will be:

V = 12 * (( 4.5 / (4.5 + 1.1)) = 9.6

If the resistors are at opposite ends of their re spective tolerance ranges, so that R1 has an actual value of 900Ω while the lower resistor has an actual value of 5.5K, the actual voltage obtained will be:

V = 12 * (( 5.5 / (5.5 + 0.9)) = 10.3

The situation becomes worse if the two resistors are chosen to be of equal value, to provide half of the supply voltage (6 volts, in this example) at their intersection. If two 5K resistors are used, and the upper one is actually 4.5K while the lower one is 5.5K, the actual voltage will be:

V = 12 * (( 5.5 / (4.5 + 5.5)) = 6.6

Whether this variation is significant will depend on the particular circuit in which the voltage divider is being used.

Common through-hole resistors may occasion ally turn out to have values that are outside their specified tolerance range, as a result of poor manufacturing processes. Checking each resis tor with a meter before placing it in a circuit should be a standard procedure.

When measuring the voltage drop introduced by a resistor in an active circuit, the meter has its own internal resistance that will take a propor tion of the current. This is known as meter load ing and will result in an artificially low reading for

the potential difference between the ends of a resistor. This problem becomes significant only when dealing with resistors that have a high val ue (such as 1M), comparable with the internal resistance of the meter (likely to be 10M or more).

When resistors are sorted into small bins by the user, errors may be made, and different values may be mixed together. This is another reason for checking the values of components before using them. Identification errors may be nontrivial and easily overlooked: the visible difference between a 1 megohm resistor and a 100Ω resistor is just one thin color band.

Labels: Electronic Components